Just in case you don’t have enough to read, here are links to the latest Music Production guides:

It’s raining in The PNW (as usual) and I’ll kick back with these as should you.

Now for a few random thoughts.

Got the power

I owe (Another)Scott for this observation. He found the following error message in the Yamaha Montage M Operation Manual:

CPU Fan Error: The instrument internal cooling fan has stopped.

CPU fan?

Yes, CPU fan. Demonstrators and punters alike have noted the snappy, responsive Montage M performance. As I thought, Yamaha have upped the host CPU in Montage M. We’ll have to wait for pictures or service manual, but I suspect multi-core (Montage gen 1 is a single core ARM) and/or a higher clock speed.

This means more power in and more power (heat) out.

I wouldn’t expect to find a massive, x86-sized blower and heat sink. Even lowly Raspberry Pi 3 (Broadcom BCM2837 quad-core ARM Cortex-A53 at 1.2GHz) needs a small cooler when running compute-intensive jobs. Raspberry Pi coolers are modestly small and light.

The new Montage M CPU probably includes a more up-to-date, integrated graphics processor, too. It would be interesting to know if the graphics processor (GPU) speeds up the Smart Morph operation. Inquiring minds want to know!

Sub display

I loves me that big old 512×64 LCD “sub display” and the way it is integrated with the rest of the Montage M workflow. The Montage M engineers took this idea from Genos “Live Control” and made it bigger and better in every way.

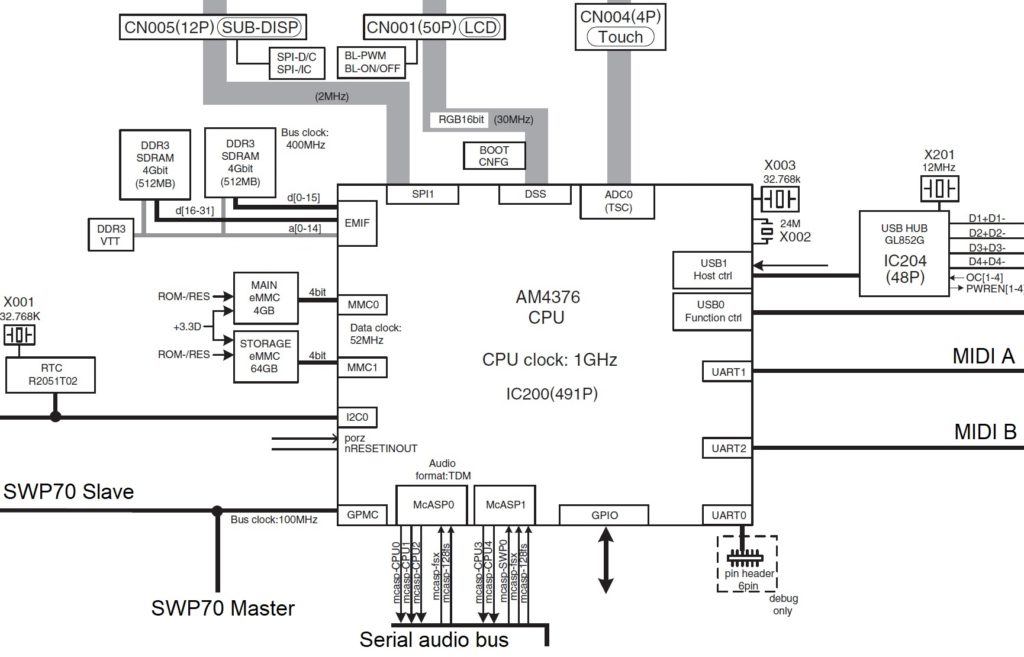

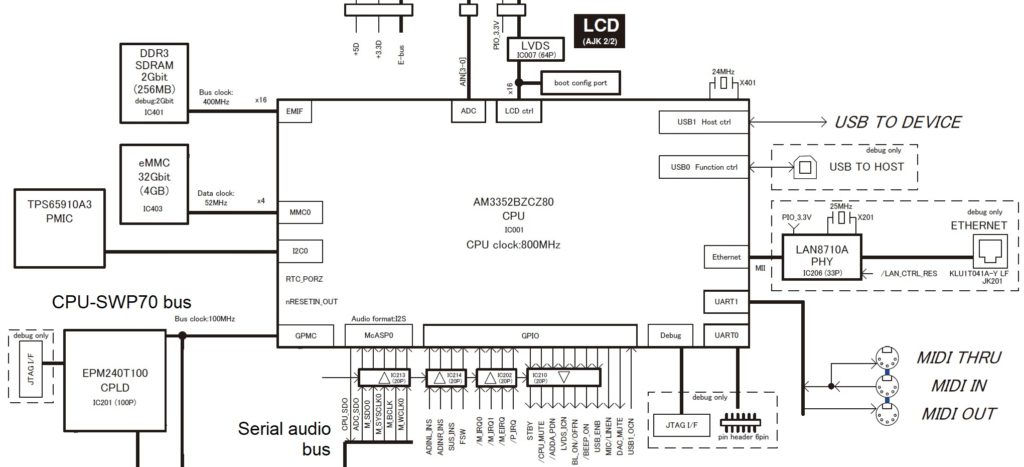

The Genos host CPU (AM4376 ARM operating at 1GHz) handled its sub display over a relatively slow, 2MHz Small Peripheral Interface (SPI) bus.

This got me thinking and speculating. The Yamaha SWX09 processor (248MHz internal clock) has a heavy weight DSP, integrated display interface, and low(er) resolution analog-to-digital converters. What if an SWX09 handles the sub display, scans the knobs and sliders, and performs AN-X synthesis? That structure and assignment of duties would make AN-X synthesis incredibly low-latency and responsive to knob and slider control. The SWX09 would need to send controller values over the E-bus to SWP70 and other destinations.

Please file this speculation under “daydreams.”

AWM2/FM-X tone generation

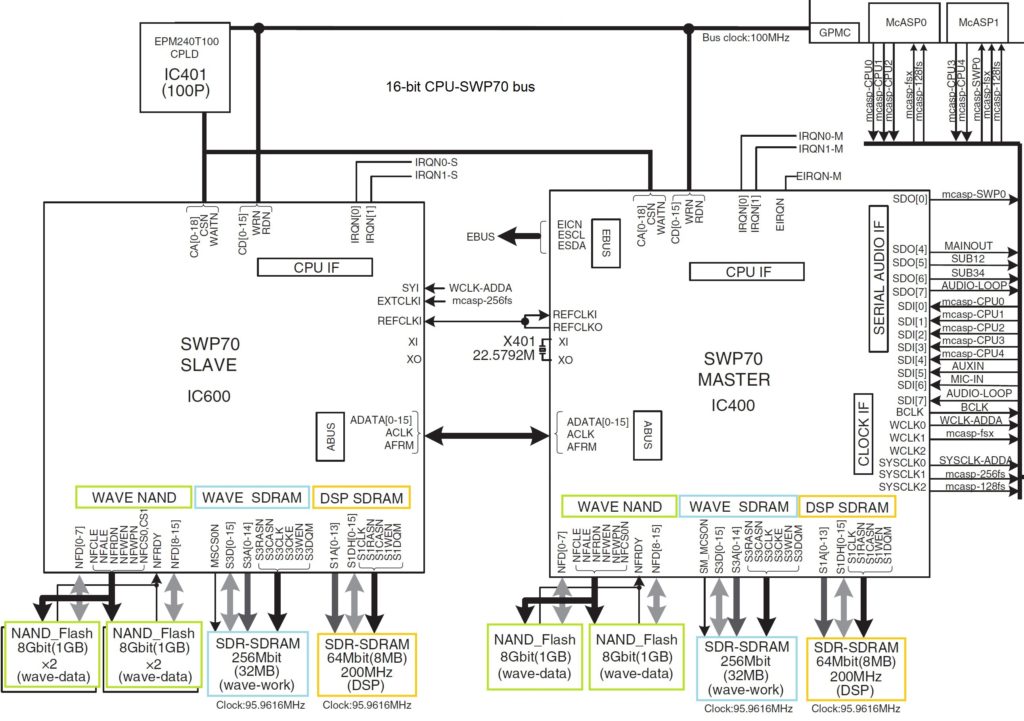

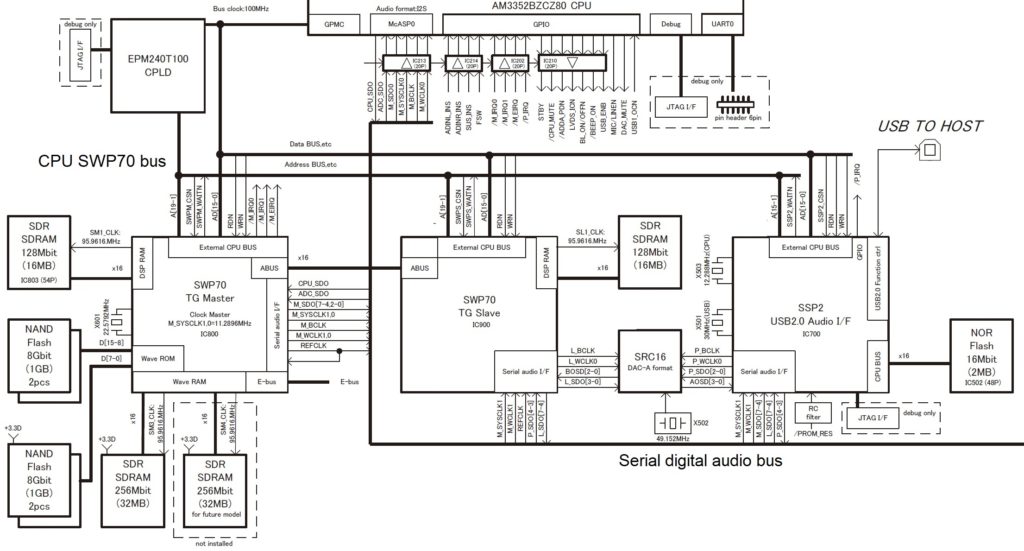

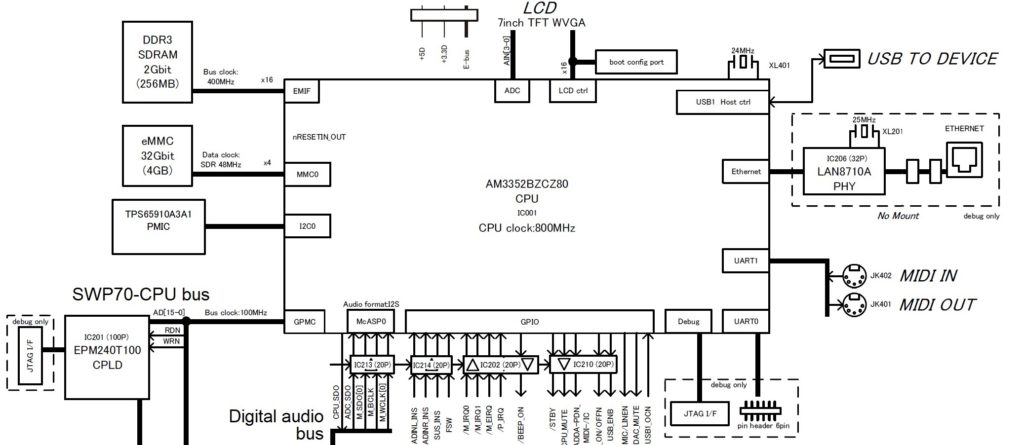

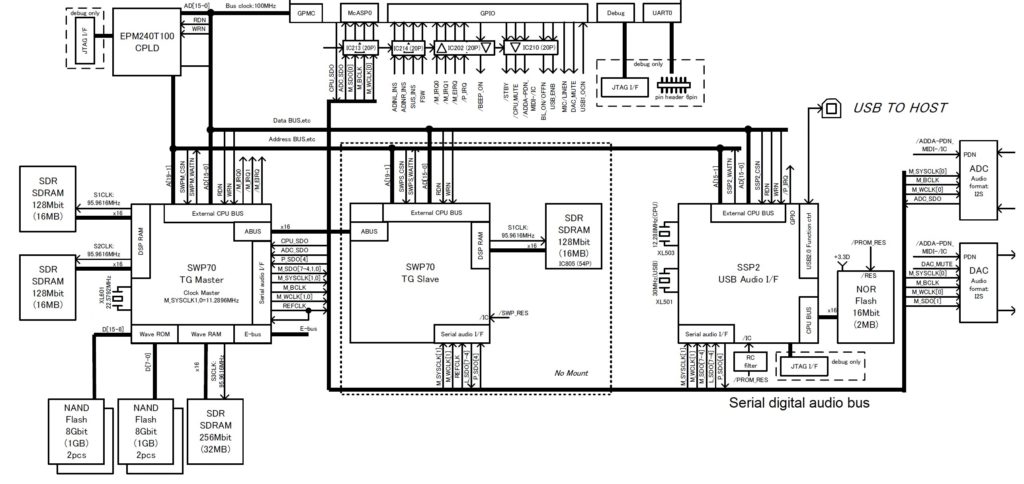

If I had to guess (and I will), Montage M has two SWP70-type “Standard Wave Processors” just like Montage gen 1. AN-X is computed by either an SWX09 or an SSP3. Both SWX09 and SSP3 are SH-2 RISC cores. The SH-2 has been a Yamaha stalwart for nearly two decades, appearing throughout a wide variety of products from audio interfaces, to mixers, to Reface, to digital pianos.

Here’s food for thought. In Montage gen 1, the Master SWP70 handles AWM2. The Master SWP70 has two wave RAM channels: one populated, one empty (“not installed”). Perhaps — perhaps — Yamaha populated the second wave RAM channel and doubled the size of the NAND flash from 4GB to 8GB.

The fly in the ointment is the stated Montage M AWM2 polyphony spec: 128 factory preset elements plus 128 user waveform elements. If both operate from the same NAND flash, then there should not be this artificial split (factory vs. user). Perhaps Yamaha added user NAND flash and wave RAM to the Slave SWP70? Or maybe this is all wet and there is a third SWP70? (See Genos internals.)

128 elements per part

As I mentioned yesterday, allowing up to 128 elements per Performance part is a big win for piano and organ voice programming. In Montage gen 1, sound designers often needed to split voice elements into several Parts, 8 elements per Part (max).

This improvement opens a can of worms with respect to real-time element assignment and activation. The E-bus carries note on/off directly from the keybed scanner to the Master SWP70. How much does the host CPU intervene? Does the SWP70 handle element assignment and activation by itself? If the SWP70 does this by itself, then Yamaha probably needed to revise the SWP70 IC, i.e., a new silicon spin and a new part number (“SWP71”).

BTW, just for kicks, someone should try programming a Performance Part with 128 elements. Hit a note, then hit a second note. What happens?

Fun with fuses

Some folk still conceptualize SWP70 as “a big ole programmable CPU”. I prefer to conceptualize the SWP70 as a collection of AWM2 pipelines, FM-X pipelines, 32 or so very simple DSP effect processors, and a very flexible digital audio mixing system. (Of course, there’s other stuff, too.) The AWM2 pipelines and FM-X pipelines are circuits dedicated to AWM2 and FM-X synthesis, respectively and specifically.

Each group of pipelines reside on their own power and clock grids. Circuit fabrication is not a perfect process. The AWM2 pipes or the FM-X pipes could suffer a fabrication flaw. During QA, Yamaha could sort parts into four categories: both AMW2 and FM-X good, AWM2 good and FM-X bad, AWM2 bad and FM-X good, both AWM2 and FM-X bad. Both sides bad is a reject.

In the cases of one side good, the bad side can be fused off. Yep, there may be fuses to cut bad pipes from the power and clock grids. Parts can be assigned to either AWM2-only duty or FM-X-only duty when a PCB is manufactured.

This is standard industry practice. The processor you are using right now probably has bad circuits fused off!

E.S.P. all over again

Dedicated pipelines are why Yamaha tone generators and polyphony are so predictable and stable. There isn’t any nonsense about effects, this or that cutting into polyphony because everything shares the same processor.

That’s why I don’t expect the Expanded Softsynth Plugin (E.S.P) to provide stellar polyphony. The initial release (“early 2024”) will support sound design. That’s a modest goal for PC-/MAC-synthesis. I wouldn’t expect too much — “all the Montage M sound while being limited to basic editing.” The full version is planned for Summer 2024.

As to development, pricing and distribution, I’m sure Steinberg will have a hand in. Steinberg completed a rent-to-own partnership deal with Splice in April 2023. Yes, Steinberg and Yamaha have caught the subscription model disease. If it’s rent-to-own, the price isn’t going to be cheap. You didn’t expect to get a Montage M for a few bucks, did you? You want to play, you gonna pay.

Copyright © 2023 Paul J. Drongowski